In printed circuit boards, reliability begins with the design and manufacturing steps.

Some PCB design and assembly jobs are too important to be handled by a team of engineers. You may benefit from partnering with a contract manufacturer who is not only well versed in Class 3 electronics, but also assists in the design process.

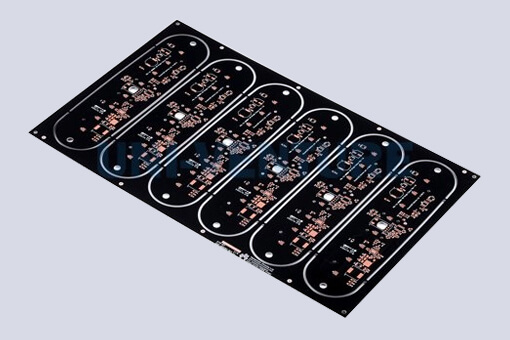

Aerospace PCB requires highly reliable printed circuit boards under extreme conditions. TCL Elektronika supplies printed circuit boards that offer a wide range of materials, composites, substrates and constructions that are very effective in the aerospace industry.

Following simple best practices helps during development and assembly for the aerospace and aviation industry. Some of them are as follows:

The aerospace and aviation industry follows standards such as AMS2750E, AS478N, AS5553A, AS9006A, AS9100D, AS9101E and AS9102B. It is worth knowing which of the the above standards and regulations are applicable for a specific job. Complicated circuits often require multi-board and multi-layer boards that must interact together. PCB design software packages with the ability to simulate temperature and power variations coupled with the ability to perform finite element analysis of hardness or strength offer undoubted advantages. If you are using a PCB assembly partner to assemble your boards, it is essential to ensure they can meet the quality and durability requirements in the aerospace industry. This may require reviewing their operational processes and quality control documentation to ensure they can help you meet all the necessary requirements. It is essential to use only high-quality components that meet and withstand the rigors of the space environment. Take the necessary measures to avoid the use of counterfeits. Guaranteeing the supply of the logistics does not cause delays and / or interruptions in production. Aerospace and aviation electronics require extensive testing, and knowing what specific testing is required is imperative. Make sure the necessary test equipment is available and fully operational and operators are well trained to handle them.

Aerospace Electronic PCB Design

You are certainly familiar with many great companies and breakthroughs in the aerospace industry. You may have also heard of the tragedies that happened when a project went wrong.

Unsurprisingly, aerospace manufacturing and design have to meet rigorous standards. Electronics in the aerospace industry often cope with harsh environments, and it may be impossible to repair them while in use - they are thousands of meters after all. With any military or aerospace electronics project, TCL Elektronika must consider:

Aerospace PCB design standards rise far above what you would see in, say, a kid's LeapFrog tablet.

Aerospace electronic components can be critical or non-critical. For example, there are PCBs (printed circuit boards) in the autopilot system on an airplane, obviously important for keeping people alive. If they fail, you have a big problem, Houston.

Conversely, there are also printed circuit boards in the seat adjustment controls of a commercial airline. These are not considered critical; if they fail, lives are not at risk. However, you must design the electronics so that it can "fail safely" and not pose a fire risk.

When considering how military and aerospace electronics are designed, plan to follow the appropriate protocols. The components and materials you use should reflect the requirements you must meet for the end use of your product. If your product is mission critical, expect longer lead times. The approval process will take much longer.

| IPC Class 1 | IPC Class 2 | IPC Class 3 | |

|---|---|---|---|

| Category | General Electronics | Dedicated service electronics | High-reliability electronics |

| Life Cycle | Short | Long | Very Long |

| Quality | Cheap | Good | Resistant to failure |

| Examples | Toys, flashlights, smartphones | Laptops, Microwaves, some mining equipment | Aerospace, military & medical appliances |

Duration PCB Design

Even if your aerospace electronics project won't go to a galaxy far, far away, it will still be a hassle to replace. Stick to high-quality components and materials that will be available for future product implementations. This is especially important when the product is used for an application that will remain in the air for months or even years. Repairs and upgrades could cost the end user a fortune.

Exact Material Specifications

Material specifications for aerospace PCB assembly and aerospace products in general are very finicky. TCL Elektronika will make sure you use exactly what you specified in the order. Any end customer or inspector you deal with will expect the same. Everything used in manufacturing and assembly will be inspected to the highest standard, checked, and double checked. For example, a component with a certain percentage of mixture of two metals will have to respect very specific tolerances.

Resistance to Difficult Environments

TCL Elektronika knows full well that the aerospace and defense industries require special radiation and thermal considerations.

We all associate extreme temperatures with exterior design challenges, such as flames escaping from the bottom of a shuttle during launch. But heat can also be a problem for internal devices. Temperatures near the engine can be several thousand degrees, for example. Since electronic devices control these motors, they must include components with high heat resistance.

RF radiation is a significant risk to be considered at atmospheric levels within the ionosphere. Ion radiation is a concern for all vehicles and systems in space, but even more so for its potential to disrupt wireless communications.

Compliant coatings are one way PCB manufacturers can protect their boards from heat, dust, or moisture.

Testing and Inspection

TCL Elektronika makes sure to carry out the appropriate protocols for testing and inspections. Testing is extremely important because it's the best way to ensure your product holds up when it counts. Failure by the electronics manufacturer to conduct proper PCB testing could endanger lives and increase liability. Thermal and vibration tests are two of the most relevant tests for aerospace products, although a variety of tests can be performed depending on the product.

Intrinsic safety is another consideration here. Some parts must be classified as "intrinsically safe" which means they are unable to release heat or electricity which can ignite the atmosphere around the product. In other words, they must prevent an explosion or fire.

Compliance

What is aerospace electronics design but a gigantic quality system? When you produce aerospace parts, each part must have several "key characteristics". These traits include:

Aerospace PCB manufacturing adheres to AS 9100, which uses the ISO 9001 standard as a basis and adds to them. AS 9100 is a quality standard, but there are other SAE standards that cover different aspects of the manufacturing process.

Other electronics manufacturing standards are used to verify manufacturing processes. One such standard is Nadcap. Aerospace and defense industry suppliers are rigorously tested to ensure their processes, employees and equipment meet all Nadcap standards.

Major aerospace and defense companies such as Boeing and Lockheed Martin sit on Nadcap's board of directors and set the standard that all manufacturers must meet to achieve certification.

A more specific example is a component that must have a specific tolerance because it has an influence on the overall product.

Regulators are hypersensitive to any kind of counterfeit or replacement part. The manufacturer of the electronics contract must warrant and demonstrate that the material path comes directly from the approved supplier. It absolutely cannot replace in a different component without your green light. It may seem obvious that unauthorized replacements would be frowned upon, but in aerospace component manufacturing it's an even bigger no-no. False parts or parts that don't follow specifications can get both you and the contractor in big trouble.

Risk

Risk is a consideration in pretty much everything we've talked about so far. But let's go a little more specifically.

You should also do your own risk assessment, including choosing a manufacturer that will meet your needs. Don't choose a company that doesn't have the ability or ability to keep up with regulatory requirements and product assembly and delivery times.

Risk

Once a satellite goes up, there is no way to swap a bad board inside it for a good one. Therefore, the failure due to heat accumulation is not acceptable. In addition, the lack of air precludes the use of convection cooling - a fan does not serve to remove the heat in the space. This leaves designers no choice but to use the metal's natural properties, conduction, to dissipate unwanted heat from a source. Although 20-layer PCB designs with 4oz copper are a common feature in the aerospace industry, heavy copper poses a substantial challenge for both fabrication and assembly. Since polyimide is the most common material to use as a substrate and is a difficult resin system to work with, fabricating a multilayer PCB with heavy copper and polyimide is a difficult task.

While heavy copper helps dissipate unwanted heat when the PCB is in active use, it also draws heat away from the SMD terminals during the reflow soldering process during assembly. The lack of heat does not allow the weld to melt and flow properly, resulting in an unreliable joint. The assembly process must compensate for this with a longer preheat time, but this also increases the chance of delamination as the copper traces now heat to a higher temperature. Likewise, once the soldering process is finished, the required cooling time is also longer, which means that the solder remains in the molten state longer than necessary. This can allow vibrations to move SMD components from their normal positions before the solder solidifies.

Encapsulated Electronics

In an airplane, most of the electronics, such as engines, are in an exposed environment. The only internal electronics would be your entertainment system, all galley lighting systems, etc. The cockpit is also a controlled environment. However, there is no distinction between the internal and external fuselage. Build the electronics the same way. They need to be encapsulated and controlled. The fuselage, engine and wing electronics are basically encapsulated in hermetically sealed boxes. So the cards themselves are not exposed to any elements. But they are exposed to temperatures and cycles of heat and cold daily.

Choose a standardized process manufacturer, choose TCL Elektronika

When choosing a manufacturer to build your aviation and aerospace circuit boards, make sure each process is standardized and repeatable. TCL Elektronika has the process controls and measurements to ensure that repeatability is always 100%. Customers can request data from the manufacturer's processes. Many satellite customers will ask for DPA type analysis, basically, destroying a good product to prove they have the right plating thicknesses, etc., all the way to SPC process control analysis for all the different processes. The design must be designed to be reliable.

Date : 28-09-2021