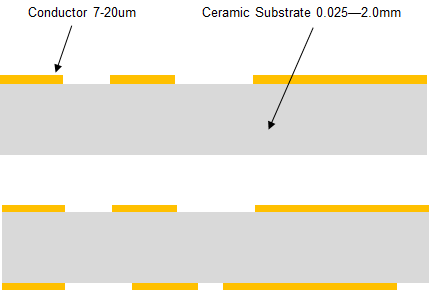

Ceramic - Thick Film

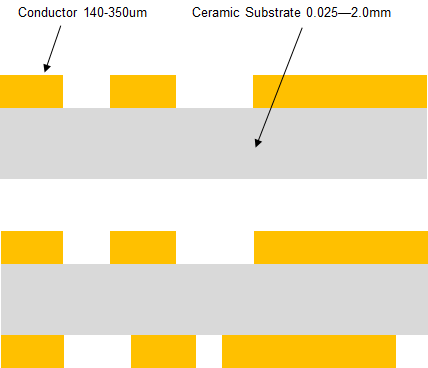

Ceramics - DBC (Direct Bonded Copper)

Disadvantages:

Applications:

Main applications are high power modules, like IGBT, CPV, or any other wide bandgap device modules.

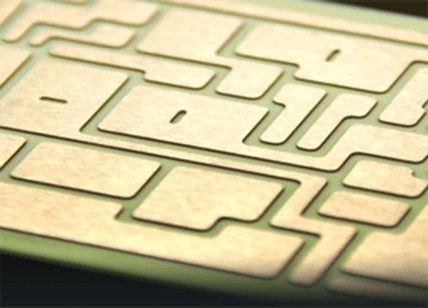

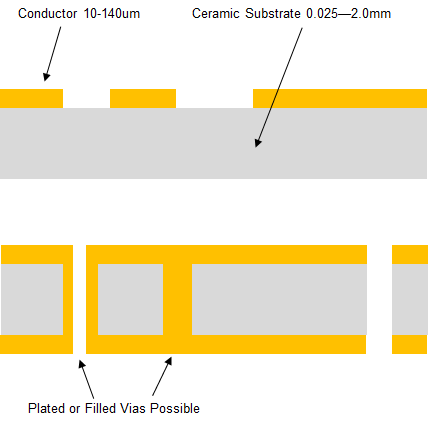

Ceramics - DPC (Direct Plated Copper)

Applications:

Ceramics - DPC vs DBC

Both DBC and DPC have the same advantages for high power applications, due to the use of a direct bond between Copper and the Ceramic substrate, therefore, the same key attributes for both of them are:

The differences come when looking at the design considerations and applications. DBC being suited to high current capacity, however limited on circuit design. DPC allowing for finer tracks and through hole connection.

Ceramic - Capabilities

| Property | DPC | DBC |

|---|---|---|

| Compatible Substrates | Al2O3 / AlN / SiN | Al2O3 / AlN / SiN |

| Substrate Thickness (mm) | 0.25/0.38/0.5/0.635.1.0/1.5/2.0 | 0.25/0.38/0.5/0.635.1.0/1.5/2.0 |

| Copper Weight (oz) | 10 - 140 | 140 - 350 |

| Panel Sizes (mm x mm) | Standard: 115 x 115mm Special: Up to 170 x 250mm |

Standard: 115 x 115mm Special: Up to 170 x 250mm |

| Finish Options | ENIG/ENEPIG/EPIG/Immersion Silver/Immersion Tin/OSP | ENIG/ENEPIG/EPIG/Immersion Silver/Immersion Tin/OSP |

| Min Track Width (mm) | 0.1 | Dependant on Cu Weight |

| Minimum Hole Dia (mm) | 0.08 | 0.08 |

| Plated Via Aspect Ratio | 5:1 | N/A |

Date : 18-10-2021